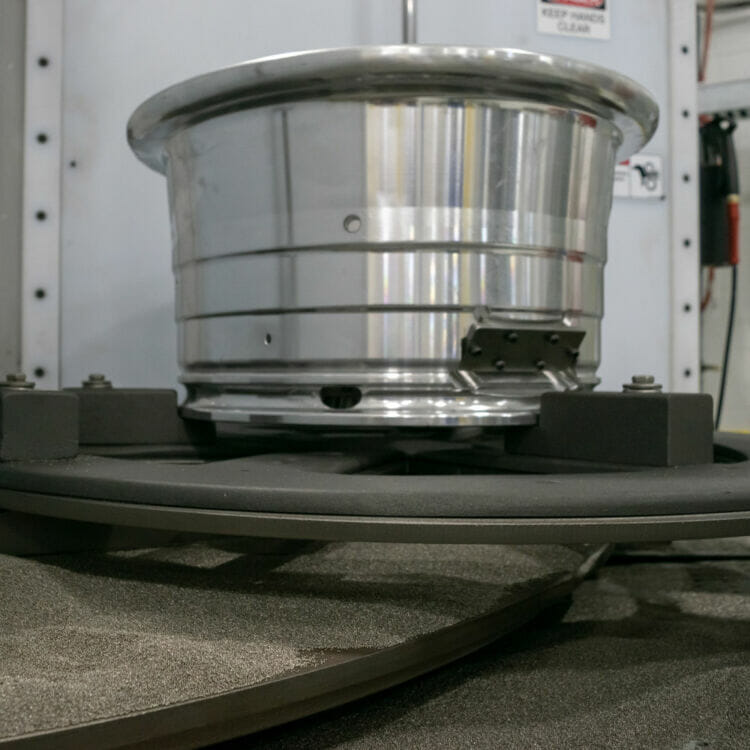

Metal Finishing Services

NAP proudly serves the aerospace industry with optimized metal finishing processes.

Metal finishing is typically the final step in the manufacturing process. In general, it is used to provide environmental protection and/or metallurgical enhancements to critical components. We offer Anodizing, Shot Peening, Painting, Passivation, and ChemFilm services. These processes help aerospace products withstand harsh environments and maximize the longevity of any part.

Our aerospace metal finishing services are specifically designed to accommodate materials used in the aerospace industry. Our commitment to quality (NADCAP Certified) we are here to serve both OEM and aftermarket customers. We are committed to high quality, fast turnaround, and competitive pricing.