Wet Painting Services

National Aerospace Processing (NAP) delivers NADCAP-accredited aerospace painting services tailored to meet the demands of the aerospace and defense industries. Wet painting is an essential process for protecting critical components, enhancing durability, and achieving precise aircraft finishing. With advanced technology, a team of expert aerospace painters, and experience meeting military and OEM specifications, NAP provides the high-quality, reliable wet painting services you need.

Types of NAP Wet Painting

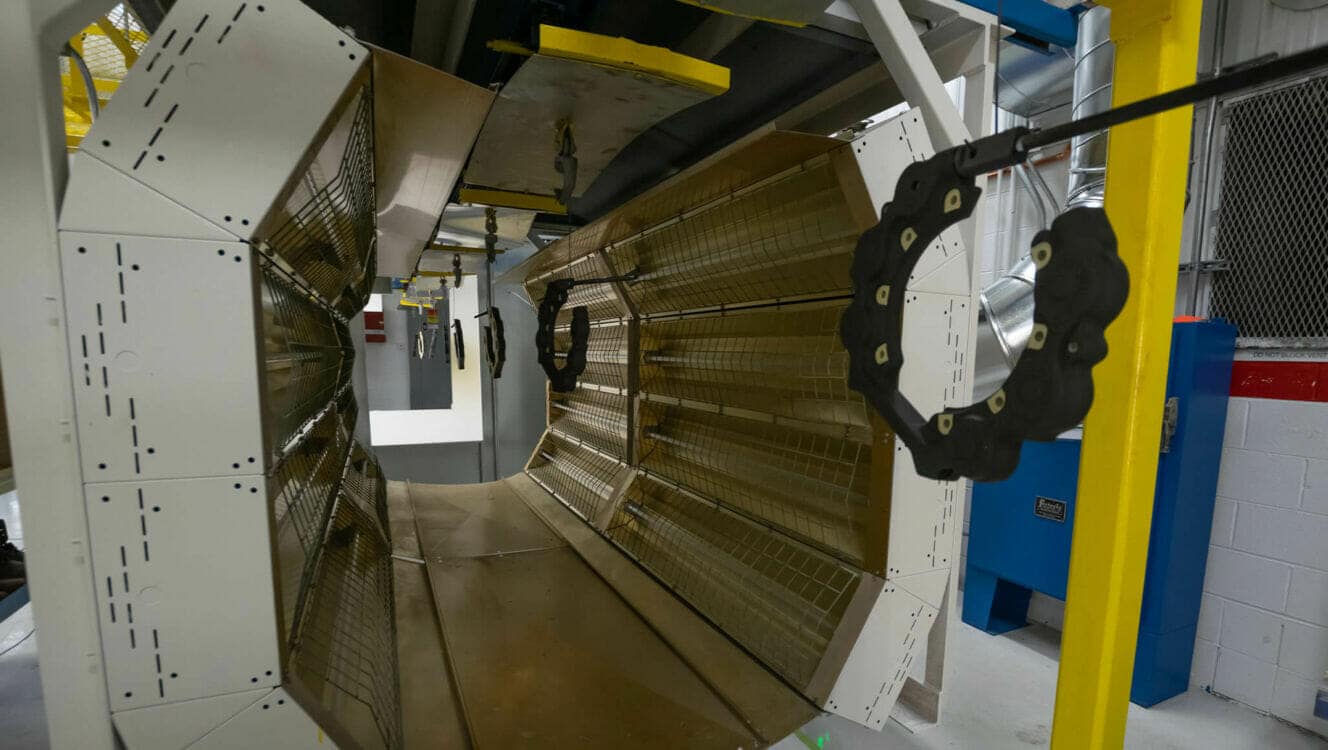

Conveyor Paint Line

Our Nadcap-accredited conveyor paint line supports high-volume aerospace painting, aircraft component coating, and precision metal finishing for aluminum, steel, and composite assemblies. Designed for aerospace and defense manufacturers, this automated wet paint system delivers consistent finishes and reduced lead times for both small precision parts and large structural components.

Features & Benefits

- Improved Process Efficiency: Automated aerospace painting ensures repeatable application, controlled dwell times, and faster throughput

- Uniform Precision Finishes: Delivers consistent adhesion and coverage for aircraft components and assemblies

- Scalable Production Capacity: Accommodates prototype runs, low-volume jobs, and high-volume aerospace production with predictable turnaround times

MIL-Spec Prime/Paint

NAP provides MIL-Spec aerospace painting services compliant with MIL-PRF-23377 epoxy primer, MIL-PRF-85285 polyurethane topcoat, and MIL-C-8514 wash primer specifications. Our military-grade coating systems enhance corrosion resistance, chemical resistance, and long-term durability for aerospace and defense components requiring strict specification adherence.

Features & Benefits

- MIL-Spec Compliance: Meets MIL-PRF and OEM aerospace coating requirements for defense and government contracts

- Enhanced Corrosion Protection: Provides long-term substrate protection in high-humidity, salt spray, and operational environments

- Tailored Solutions: Delivers customized aircraft finishing to meet precise specifications.

CARC Paint (Chemical Agent Resistant Coating)

Our CARC paint services meet MIL-DTL-53072 requirements and other defense coating specifications for Chemical Agent Resistant Coating systems. These specialized military coatings are engineered to resist chemical exposure, decontamination procedures, and extreme operational conditions in aerospace and defense environments.

Features & Benefits

- Chemical Agent Resistance: Protects components from harsh chemicals and hazardous agents

- High-Performance Durability: Maintains coating integrity under abrasion, weathering, and operational stress

- Defense-Grade Application: Supports mission-critical aerospace and military equipment finishing requirements

AMS Standard Painting Services

NAP’s Aerospace Material Specification (AMS) painting services ensure compliance with aerospace coating standards governing performance, durability, and material compatibility. We apply AMS-compliant primers and topcoats for aircraft components, structural assemblies, and precision metal parts used in aerospace and defense manufacturing.

Features & Benefits

- AMS Specification Compliance: Meets aerospace material standards for coating performance and consistency

- Long-Term Environmental Protection: Enhances resistance to corrosion, UV exposure, and operational wear

- Precise Color & Finish Control: Ensures accurate color matching, gloss levels, and surface uniformity for aerospace applications

General Wet Painting Process

At NAP, our NADCAP-certified wet painting services ensure optimal performance and consistency for every component. We begin with a thorough surface preparation, which includes cleaning and degreasing the metal surface, followed by surface treatments like etching or phosphating to improve paint adhesion, depending on the application and required coatings. Next, our expert aerospace painters apply high-quality coatings, including primers and topcoats, using advanced spray guns or equipment to achieve a durable finish.

As the curing process is critical, we use infrared curing ovens to dry and harden the paint, ensuring it meets aerospace standards. To further enhance protection and performance, our experts can also apply hand sealants and dry film lubricants as required. Throughout the process, we maintain strict quality control measures, inspecting each component for proper coverage, finish, and performance.

Why Choose NAP for Wet Painting

National Aerospace Processing sets the standard for excellence in aerospace painting. Our highly-trained metal painters apply coatings that meet stringent aerospace and military specifications. With NADCAP-accredited painting (AC7108/1) and a NADCAP-certified aerospace quality system (AC7004), our certifications ensure that every component meets or exceeds industry requirements for compliance and quality.

Our Northeast Ohio facility is well-equipped to provide high-quality metal painting services for components of all sizes, with two paint booths, a conveyor paint line, and infrared curing ovens. We also ensure precise color matching and account for tolerance requirements to ensure that every project meets the highest standards in aerospace finishing, delivering quality you can rely on.

Time Is Money – Contact Us Today!

Contact our technical staff to learn how National Aerospace Processing can help you reduce lead times, streamline your processes, and deliver top-notch quality. Request a quote or reach out for more information today.